Research and Production Enterprise

Electrotech

Research and Production Enterprise Electrotech is a developer and manufacturer of process monitoring and control systems for fluid injection into oil and gas wells, including Well Cementing Process Control Systems SKTsS-01.

The Company was founded over 20 years ago; SKTsS-01's, logging stations, their components and SPA (spare parts and accessories) kits have been supplied for over 15 years.

The SKTsS-01 is used in the oil and gas industry for operations as follows:

• Well drilling

• Well cementing, liner cementing

• Well workover

• Remedial cement squeeze

• Well kill

• Coiled tubing

• Hydraulic fracturing (fracking) technology

• Bottom-hole treatment (BHT) with aggressive media

RELIABLE MEASURING INSTRUMENTS

FOR VARIOUS APPLICATIONS

The same SKTsS-01 package can be used in various technologies where fluids of different densities and compositions are pumped over.

The SKTsS-01 measures, logs, and monitors the following parameters:

• Density from 750 to 2400 kg/m3

• Flow up to 180 m3/h

• Pressure up to 40 MPa

• Temperature between minus 40 and plus 100 °C

Primary sensors:

• Coriolis flowmeters in various high-pressure and low-pressure modifications

• Electromagnetic flowmeters REM

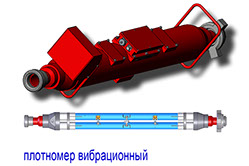

• Vibration density meters

Features of SKTsS-01 instruments

• Easy to mount with quick release connectors

• Operating in a high-pressure discharge line

• No isotopic radiators

• Field-calibrated

• Compact design

• Easy to transport

• Short warm-up time

• Potential enhancement of functionalities

• Minimum error among similar products

• Per-second work progress display

• Increased reliability

• Impact-resistant

Systems can be supplied either as mobile (portable) versions or as a part of various units (on vehicle chassis, sled, or trailers, as a part of laboratories).

Description

The Well Cementing Process Control System SKTsS-01 manufactured by Electrotech, Izhevsk, is intended for logging of

• density

• flow rate

• pressure

• temperature

during various operations involving injection of variable-density fluids.

Let us review operation of the station on a typical example of well cementing. Let's assume that single-stage reservoir annulus cementing is required. Based on parameters of the well structure, a work plan shall be executed specifying injection phases and amounts. Initial planned parameters are entered into the station's application.

The station's measuring tube is mounted in the discharge line downstream of the manifold unit and immediately upstream of the cementing head. Everything that enters the well passes through the measuring tube. Signals from sensors of monitored parameters are converted with a controller into a digital electric signal, which goes to the operator's workstation. Data are transmitted either via a power supply cable through the power supply unit or via a radio communication line.

The computer application displays process parameters as plots on the monitor screen and on the remote digital display (indicator). It is possible for the cementing engineer to monitor the injection parameters throughout performance of works.

SKTsS-01

Well Cementing

Control System

SKUTP-01

Process Monitoring and Control System

The SKUTP-01 system includes a primary sensor—a Coriolis flowmeter with a density measurement function, which allows you to monitor values of the following parameters of fluid feed into the well:

• density

• flow rate

• pressure

• temperature

The operator workstation and the process equipment of the plant are mounted on the frame of a vehicle chassis, trailer, sled, etc. The SKUTP-01's measuring device is built into the discharge line of the plant. At low temperatures, a hydraulic unit and a measuring device are heated by the vehicle's exhaust gases.

The Coriolis flowmeter being a part of the SKUTP-01 mobile package is supplied in a thermal container, which makes it possible to avoid temperature differentials and mechanical impacts during transportation.

Information received from the flowmeter is transmitted to a remote operator workstation via cable connections (reel units) or at a distance of the Wi-Fi signal; herewith, the operator workstation can be transferred to any other place, with no delays in technologies.

The values of measured parameters from the flowmeter occur at an external data storage medium (BVI-01, laptop, tablet) and are displayed at a remote display BIV 3-6, which can indicate up to 6 parameters of process solutions injected in the well. Injection results (reports) are generated as graphs and tables reflecting the parameter values throughout the work performance process.

The mobile package's weight is no more than 150 kg.

Flowmeter dimensions are no more than 1710х200х340 mm.

The average time of equipment installation does not exceed 10 minutes.

The warm-up time is no longer than 10 seconds.

Supply voltage requirement is ~220 V or⎓12/24 V.

There is a possibility of data transmission to the customer's remote server via a GPRS signal or a satellite connection, in which case a special version of server software will be supplied and the SKUTP-01 operator's software will be upgraded.

Technical Support

Commissioning and Warranty Service:

Aleksandr Nedopekin

email: avn@eteh.su

+7(901)707-10-21

Hotline for equipment operation issues

+7(3412)230-350 ext. 204

Commissioning and Warranty Service:

Dryahlov Danyil

email: ds@eteh.su

+7(922)682-34-31

Repair and Service Support:

Dmitriev Andrey

email: service@eteh.su

+7(3412)230-350 ext. 222

Click here to download the Application for Repair form. Fill and send the form to my email: - service@eteh.su

Activation Usb-keys

Commercial Department

Voronchihin Vladimir

Commercial Director

email: vladv@eteh.su

+7(3412)230-350 ext. 201

Vadim Kiselev

Sales Manager

email: vadim@eteh.su

+7(3412)230-350 ext. 207

Mihalicin Georgy

Sales Manager

email: gm@eteh.su

+7(3412)230-350 ext. 208

Our managers will help you to make your choice correctly.

Data sheet

Geography of Our Partners

Contacts

CALL US OR WRITE TO US:

+7 (3412) 230-350 (multiline) | office@eteh.su

OUR ADDRESS

ul. Proezd Deryabina 2/32, Izhevsk,

426000, Russia

eteh.su

Commercial Department

Business hours 8.00 AM to 5.00 PM

Lunch hours 12.00 to 1.00 PM